Transform your steam process to completely fossil-free

– economically

Industrial steam and heat production processes rely on fossil fuels, resulting in significant carbon dioxide emissions. Industrial process heat production accounts for an 18% share of the entire energy consumption in Europe, with the majority of this production relying on fossil fuels. Elstor offers an efficient and clean alternative to the use of fossil fuels.

OUR SOLUTION

Genuinely fossil-free steam for process industries

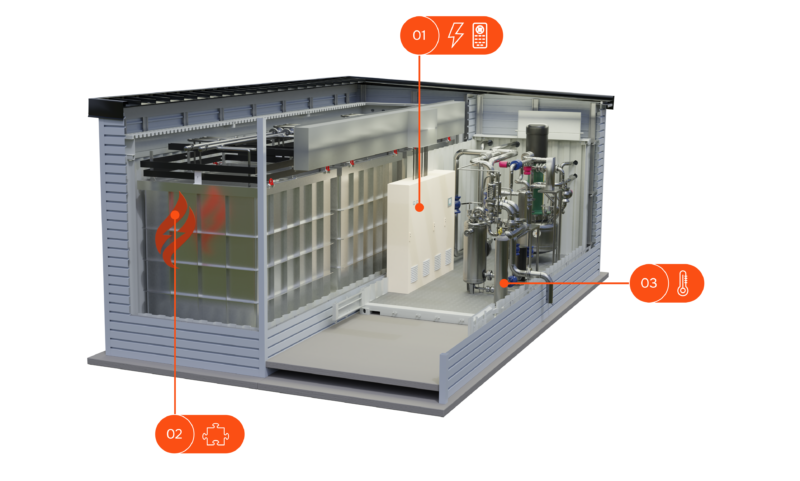

We replace fossil fuels cost-effectively in industrial steam and heat production, reducing annual CO2 emissions by up to 480 tons with a single Elstor storage unit. Switching to Elstor’s system improves steam production efficiency without additional costs or impacts on production.

How does it work

Charge with inexpensive electricity and use it when needed

Our thermal storage solution efficiently stores electricity from the cheapest hours of the day as thermal energy. The stored energy is then used to produce steam. The operating costs of the equipment are competitive with fossil fuels. In addition to cost savings, the flexible steam production solution provides protection against market fluctuations.

Charging with electricity during the lowest price periods

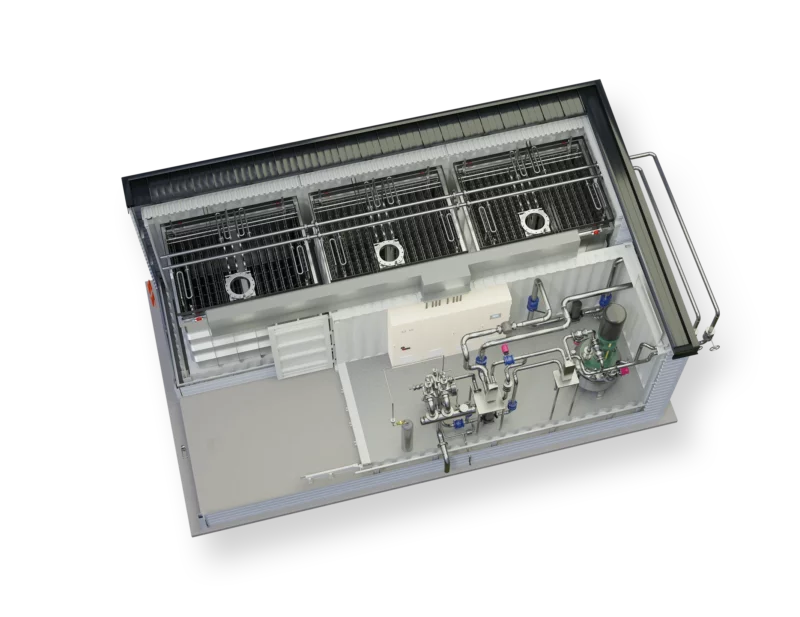

Stored in a patented high-temperature energy storage

Discharged from storage as steam when needed

For whom

Real-world tested energy storage for the process industry

Elstor’s energy storage systems have been in use in the process industry since 2021. The operational experiences have been positive both in terms of cost reduction and production flexibility. Elstor’s device is suitable for various industrial sectors due to its flexible steam production.

Food Industry

Chemical Industry

Industrial laundries

Other process industries

References

News

Ready for change?

This is how we make your processes fossil-free

Clean electricity, thanks to Elstor’s thermal storage, is a cost-effective alternative to fossil fuels. The technical specifications of the storage may vary by application, but the emissions remain at zero. Contact us, and we will provide profitability calculations for a customized system tailored to your needs.

Kari Suninen

CEO

Tuomo Honkamäki

Sales

Explore next