Solution & Technology

Genuinely fossil-free steam for the process industry

Our solution

Power-to-heat thermal energy storage

The Elstor solution is a power-to-heat thermal storage system that enables cost-effective heat and steam production with renewable electricity. Our patented solution is based on optimized remote-controlled energy storage technology that stores electricity as thermal energy.

Clean and emission-free energy

Cost-effective

Immediately available technology

Calculated based on the usage of our 10 MWh unit. Annual steam production in calculations: 3000 MWh.

| Oil-fired boiler | LPG boiler |

|---|---|---|

0 t CO2 emissions | 877 t CO2 emissions | 778 t CO2 emissions |

210 k€ annual running costs | 490 k€ annual running costs | 310 k€ annual running costs |

Competitive investment payback period | – investment payback period | – investment payback period |

Don’t you believe? Clean electricity is a cost-effective alternative to fossil fuels, thanks to Elstor’s thermal storage. Contact us, and we will provide you with customized profitability calculations for your system.

How does it work

Charge with inexpensive electricity and use it when needed

Our thermal storage solution efficiently stores electricity during the cheapest hours of the day as thermal energy. The stored energy is used for generating heat and steam. The operating costs of the equipment are competitive with fossil fuels.

Charging with electricity during the lowest price periods

Stored in a patented high-temperature energy storage

Discharged from storage as heat or steam when needed

References

Technology

Optimized energy storage technology that stores electricity as thermal energy

High discharge power and efficiency makes the Elstor storage system versatile and suitable for a wide range of varying heat and steam needs

The storage capacity does not degrade over time

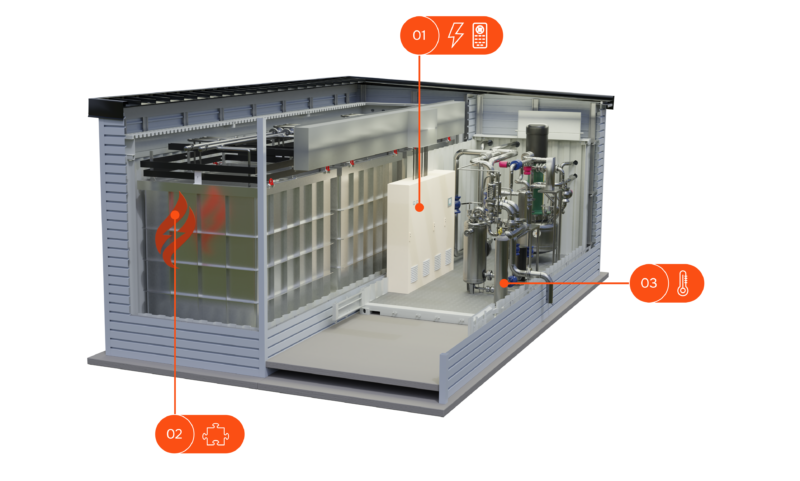

Controlled charging and discharging

Efficient storage with low heat losses.

High discharge power and efficiency

Modular and mobile

Real-time system monitoring and autonomous optimization

Technical specifications

High discharge power and efficiency

The charging power of Elstor’s energy storage depends on the storage capacity but can be adjusted to fit the customer’s needs. High discharge power is achieved through dense storage material and efficient heat transfer.

Charging power:**

Storage capacity:

Discharge power:**

* Values for a single modular 5-20 MWh unit. System can be scaled up by duplicating these units.

** Charging and discharging powers are optimized according the customers needs.

Steam pressure:

Steam temperature

Charge & Discharge response time:

Flexibility range:

Frequently asked questions

Our technology is versatile and suitable for various processes.

With a 20 MWh Elstor unit, it is possible to efficiently cover an annual heat demand of up to 10 000 MWh. Technically, the device is capable of even higher consumption, but the benefits of optimization decrease as the consumption becomes excessive.

The payback period is calculated by comparing Elstor operating costs to the current heat production method, and therefore, the estimate varies depending on the specific case. Electricity and previous fuel prices vary by location.

The carbon footprint of the device’s manufacturing has been calculated, and it is offset within approximately 6 months of the device’s use.

Start by contacting us. The process begins with gathering basic information and by doing profitability calculations for the system tailored to your facility.

Ready for change?

This is how we make your processes fossil-free

Clean electricity, thanks to Elstor’s thermal storage, is a cost-effective alternative to fossil fuels. The technical specifications of the storage may vary by application, but emissions remain zero. Contact us, and we will provide profitability calculations for a customized system tailored to your needs.

Kari Suninen

CEO

Tuomo Honkamäki

Sales

Explore next